Contact Us

P.O. Box 168

Schofield WI, 54476 United States

8:00 AM - 5:00 PM

PrimXCompositeJointless. Stronger. Thinner.

Steel-Fiber Reinforced, No-Shrink Concrete Floors with No Saw Cuts

The first jointless concrete floor with no saw cuts, PrimXComposite is a steel fiber-reinforced, no-shrink concrete flooring system. PrimXComposite contains steel fibers and two types of add mixtures combined with ready-mix concrete to create a composite material. It requires no joints or saw cuts within each pour, eliminating a mile or more of joints per typical large-scale placement.

Visit the primxna.com website.

Why Choose PrimXComposite?

- Jointless, No Saw Cuts

- No Shrinkage

- Virtually Crack Free

- Up to 60-Percent Thinner

- Higher Load Capacity

- No Rebar

- Flatter Surface, No Curling or Joint Sealant

- Durable with Less Maintenance and Longer Life

PrimXComposite eliminates joints, saw cuts and post-installation problems, increases productivity, and reduces equipment repair. Up to 60-percent thinner than traditional concrete slabs, PrimXComposite has a much higher load-bearing capacity than traditional designs and allows racking to be placed without joint consideration.

Build Your Businesses On the Future of Concrete

More than 160 million square feet of PrimXComposite floors and pavements are in service in distribution centers, warehouses and manufacturing facilities around the world.

PrimXComposite is a game-changer compared to traditional concrete, providing unmatched durability, affordability and efficiency — while improving safety and sustainability. See how PrimXComposite floors outperform traditional concrete in various industrial applications.

Disitribution & Warehousing

Strong, durable PrimXComposite floors are exceptionally flat — making them the smart choice for distribution and warehousing.

Manufacturing

Is automation part of your manufacturing vision? Continuously smooth and uninterrupted PrimXComposite floors are ideal for growing automation robotics applications in manufacturing and warehousing.

Cold Storage

Cold storage and food processing facilities demand cleanliness. PrimXComposite floors are ideal as they eliminate the joints where listeria & other contaminants collect.

Outdoor Pavement/Roads

Want to be part of the future of pavement with fewer joints and less cracking? PrimXComposite pavement requires fewer costly repairs and maintenance. Get in on the future of PrimXComposite.

Concrete Reality

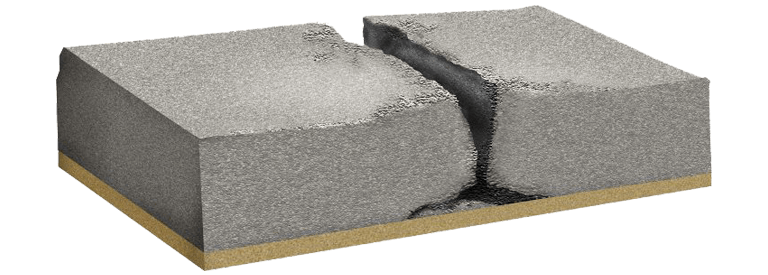

Advancements in composite materials, such as carbon fiber, plastics and polymers create thinner materials with increased strength and performance. While other materials have been improved, concrete has been virtually unchanged since the early 1820s. Traditional concrete:

- Is strong in compression, but weak in tension

- Is considered a quasi-brittle material, like ceramic (china)

- Needs to be cut in anticipation of cracks, sawing joints every 12 to 16 feet (3.64 to 4.87 meters)

- Requires steel rebar for reinforcement

- Curls at joints, causing deterioration and reducing productivity

- Requires regular maintenance and high repair costs

Traditional Concrete: Curling at saw cuts and joint damage.

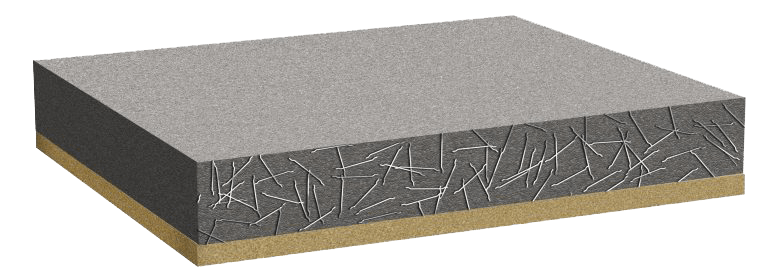

PrimXComposite: Jointless, stronger and thinner, doesn't curl.

The PrimXComposite Difference

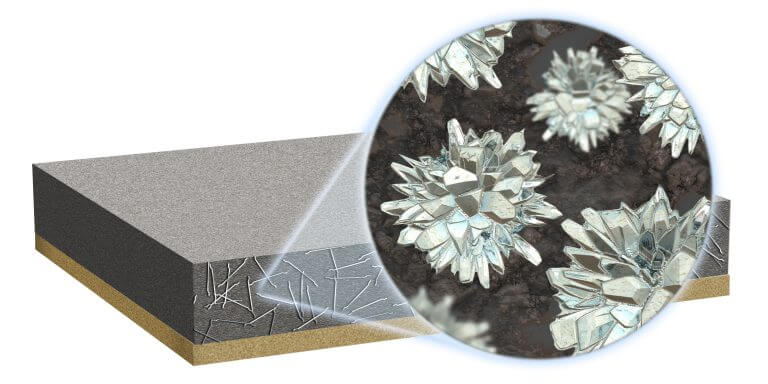

During wet cure, the PrimXComposite system absorbs water, causing a delayed chemical reaction. The additives in PrimXComposite form a micro-scale composite structure, including crystals, that expand and compress the internal concrete matrix. This expansion puts the steel fibers in tension creating a permanent pre-stress compression. The patented application allows for the dramatic thinning of slabs from traditional design.

PrimXComposite Floors

- Are engineered to exceed design load requirements

- Increase material handling productivity

- Reduce equipment maintenance costs

- Allow storage racks to be placed and moved anywhere needed

- Are virtually maintenance free

- Have a significantly longer life cycle

PrimXComposite is eligible to earn LEED credit and has many sustainability benefits. It uses less material, eliminates hazardous silica dust from joint sawing, and reduces carbon dioxide emissions by reducing cement content.

Trusted by the most sophisticated companies worldwide, over 60 million square feet of PrimXComposite is in service today. PrimXComposite is the most stable and advanced concrete flooring product on earth.